For a correct application of any surface treatment, the state of the surface on which it is to be applied is essential.

Because the parts on which the coating is to be applied come from previous processes (stamping, machining, threading, heat treatment, etc…), they must be subjected to cleaning processes prior to the deposition of the coating, otherwise we may find problems of adhesion or even non-coating. This is what is called the preparation phase within the coating processes.

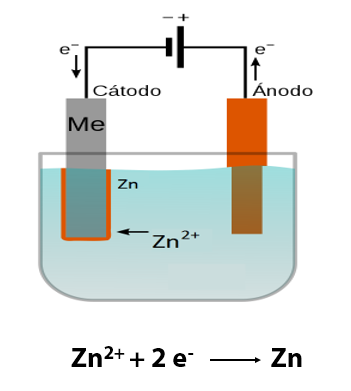

Within the coatings that we apply at INELCA, we can differentiate between two large groups, electrolytic (Zn,ZnNi, ZnFe) and non-electrolytic (Zn flakes), and each of them has a different type of preparation:

Electrolytic:

The preparation phase of electrolytic coatings consists mainly of three stages: chemical degreasing, electrolytic degreasing and pickling.

i)Chemical degreasing: This is an alkaline phase, normally based on soda, responsible for eliminating the oils from the mechanisation of the parts or from the threading processes.

ii)Electrolytic degreasing: This is an alkaline phase, normally based on soda, in which the cleaning effect of the chemical degreasing is added to the mechanical action due to the generation of gas on the surface of the part. This gas is generated by a chemical reaction when an electric current is applied. Thanks to this mechanical action, it is possible to clean up oil residues occluded in the pores of the parts.

iii)Pickling: This is an acidic phase in which metal remains and oxides present in the parts are eliminated, both those that come from natural oxidation and those that may be produced in heat treatments.

In this phase the intermediate coatings for storage that the pieces can have are also eliminated.

The most common acids used in this phase are hydrochloric or sulphuric, to which inhibitors are added to prevent over-attacking of the parts and to minimise possible hydrogen embrittlement.

Zn flakes:

Zn flakes processes, to avoid hydrogen embrittlement processes, have a different preparation. The most common consists of chemical degreasing and shot blasting.

i)Shot blasting: Mechanical cleaning process that consists of projecting abrasive material onto the parts.