Products

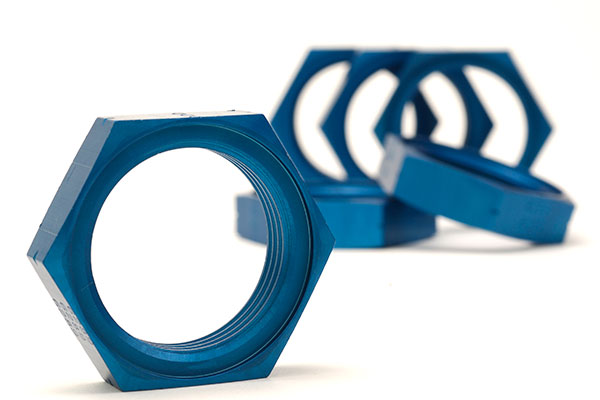

Our activity is developed in order to improve the protective properties of metal surfaces, provide new features to favor subsequent treatments and even give it a decorative finish

In the following sections the offer of products that Inelca develops for the treatment of metallic surfaces is presented, as well as the complementary services that we integrate in our organization in order to offer an increasingly complete and satisfactory offer to the client.

We offer a customized global solution for each client adapting to their needs at all times.

Metal surface coating / Electrolytic coatings

METHOD

RACK · BARREL

+300 HOURS

METAL CORROSION

BLACK · WHI TE · YELLOW

SEALINGS CORROSION RESISTANCE · FRICTION COEFICIENT

An electrolytic process that produces bright Zn deposits on steel, zamack and copper parts. The Alkaline Zinc coating has the purpose of anticorrosive protection, achieving an excellent thickness distribution compared to other Zinc deposition processes. By means of the application of seals in the final phase of the process it is possible to increase the resistance to corrosion, as well as to parameterize the coefficient of friction according to the requested specification. Following the environmental conservation policy, we have eliminated Cr VI from all of Inelca’s production processes.

METHOD

RACK · BARREL

1.500 HOURS

METAL CORROSION

BLACK · WHI TE · YELLOW

HIGH RESISTANCE TOP COAT · FRICTION COEFICIENT

An electrolytic process that produces bright Zn deposits on steel, zamack and copper parts. The Alkaline Zinc coating has the purpose of anticorrosive protection, achieving an excellent thickness distribution compared to other Zinc deposition processes. We apply an additional layer of TOP COAT on the electrolytic processes in order to increase corrosion resistance and achieve a more homogeneous appearance. Following the environmental conservation policy, we have eliminated Cr VI from all of Inelca’s production processes.

METHOD

RACK · BULK

1.500 hours

METAL CORROSION

SI LVER · BLACK · BLUE · GREEN

TOP COATS INORGANIC · ORGANIC

Surface protection coating consisting of Zn and Al sheets joined by an inorganic binder that acts as a sacrificial metal. Due to the application characteristics of this coating, it does not present hydrogenation brittleness, therefore, it is recommended for high resistance screws (10.9 and higher).

By applying TOP COATS on the basis of ZnAl, it is possible to increase the resistance to corrosion and parameterise the coefficient of friction for each of the specifications. Our mass application is made by means of centrifuges specially designed for a greater uniformity in the coating, as well as to avoid accumulations. In accordance with the environmental conservation policy, all the lamella processes applied are chromium-free.

METHOD

RACK · BARREL

2.000 HOURS

METAL CORROSION

TRANSPARENT · BLACK

SEALINGS CORROSION RESISTANCE · FRICTION COEFICIENT

Electrolytic process of zinc nickel alloyed with a percentage of deposited nickel ranging between 12 and 16%. This type of alloy is widely used in automotive applications providing high corrosion resistance. It also has excellent properties such as low corrosion due to contact with aluminium, good wear resistance, stability at high temperatures (200ºC) and low brittleness due to hydrogenation phenomena. By means of the application of seals in the final phase of the process it is possible to increase the resistance to corrosion, as well as to parameterize the coefficient of friction according to the requested specification. Continuing with the environmental conservation policy, the processes used are alkaline and Cr VI has been eliminated from all of Inelca’s production processes.

METHOD

BARREL

3.000 HOURS

METAL CORROSION

TRANSPARENT · BLACK

HIGH RESI STANCE TOP COAT • FRICTION COEFICIENT

Electrolytic process of zinc nickel alloyed with a percentage of deposited nickel ranging between 12 and 16%. This type of alloy is widely used in automotive applications providing high corrosion resistance. It also has excellent properties such as low corrosion due to contact with aluminium, good wear resistance, stability at high temperatures (200ºC) and low brittleness due to hydrogenation phenomena. We apply an additional layer of TOP COAT over the electrolytic processes in order to increase the corrosion resistance in the salt fog chamber and ensure compliance with the requirements of climatic cycles. Continuing with the environmental conservation policy, the processes used are alkaline and Cr VI has been eliminated from all of Inelca’s production processes.

METHOD

RACK · BARREL

+360 hours

METAL CORROSION

TRANSPARENT · BLACK

SEALINGS CORROSION RESISTANCE · FRICTI ON COEFICIENT

An electrolytic process to obtain ZnFe alloy deposits with an iron content of 0.3-0.6%. Alkaline ZnFe coating provides uniform deposits with greater corrosion resistance than classic Zn coatings. Through the application of seals in the final stage of the process it is possible to increase the resistance to corrosion, as well as to parameterize the coefficient of friction according to the requested specification. Following the environmental conservation policy, we have eliminated CrVI from all of Inelca’s production processes.

METHOD

RACK · BARREL

+600-800 HOURS

METAL CORROSION

TRANSPARENT · BLACK

HIGH RESISTANCE TOP COAT · FRICTION COEFICIENT

An electrolytic process to obtain ZnFe alloy deposits with an iron content of 0.3-0.6%. Alkaline ZnFe coating provides uniform deposits with greater corrosion resistance than classic Zn coatings. An additional layer of TOP COAT is applied to the electrolytic processes in order to increase corrosion resistance and achieve a more homogeneous appearance. Following the environmental conservation policy, we have eliminated CrVI from all of Inelca’s production processes.

Types of materials

Materials on which we apply our coatings